Posted on 8/4/2021 by Da-Lite Team

Across the industry, audiovisual designers and installers have encountered the limitations of historic buildings and other situations where power may not be practical.

As video becomes more ubiquitous in all kinds of public spaces, expectations also increase for video infrastructure to be aesthetically integrated. These expectations extend to historic buildings as well as those with power-access challenges, or when hiring an electrician may be impractical.

In the case of projection screens, sometimes the best wall for the screen is the most inaccessible; in other situations, users may want to relocate a screen as needs change.

A fixed-frame screen traditionally may have been sufficient for these applications and that is the primary solution many users have deployed, whether because of lack of proximate power, or because a motorized screen was too expensive.

What if there was a wire-free motorized option?

Let’s look at the innovative Tensioned Designer Contour® Electrol® and Designer Contour Electrol projection screens from Da-Lite. These ceiling or wall-mounted electric screens, available in diagonals up to 110” in 16:9 HDTV format and 113” in 16:10 wide format, offer simple installation with the benefit of a smaller housing. A variety of finishes and options make these seamless additions to any room.

But one of the most important innovations to this product offering is the option for wire-free installation, something that can be done now without compromising screen surface selection or size. The Agility™ Battery Motor option (lithium-ion) is ideal for no-fuss installations or where flexibility is required to retrofit historic buildings or environments when wiring electricity becomes project-prohibitive.

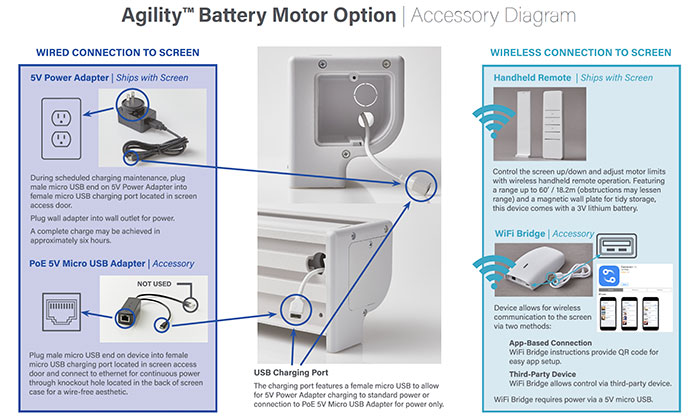

This optional lithium-ion battery lasts over 200 cycles on a single charge via micro-USB port, with wireless handheld remote operation, and up to 16K-ready screen surfaces -- no wiring required.

A Wi-Fi Bridge accessory allows for wireless connection to a mobile app where the screen can be controlled up and down as well as battery life indicator. In addition, the accessory al-lows for control through a third-party device.

The PoE 5V Micro-USB Adapter accessory keeps the battery charged between uses. Connect when needed or leave connected for maintenance-free operation.

About the Engineering

Like many innovations, the genesis was a change in underlying technology — in this case, motors and PoE. “Really it all started with motors becoming available that were strong enough to lift our projection screens and small enough to be wireless,” says Brian Schwartz, Product Manager at Da-Lite. “That’s when we started to think about everywhere this would really help out -- a brick wall, or anywhere else that would be awkward or ugly to run cable. It had been a gradual change; innovations tend to move from smaller to larger in these types of tubular motors, and from general applications into AV.”

“This development supported a request we were getting from the market,” says Wendy Cox, Director of Product Management at Da-Lite. “We were hearing ‘it would be really nice if you had a solution for these situations where users don’t want to use a fixed-frame screen, and they don’t want to be limited to screen locations by power outlets, and they don’t want to run new cable or re-arrange a room.’”

“Our R&D department had been looking to our suppliers for new things coming out,” Schwartz adds. “The team brought the motor in and tested it out. When they saw some promising results, they looped us in for product design.”

Once Da-Lite decided to use the motors, the process of qualifying them and testing them began. Because the brand maintains a distinct industry reputation, the product had to be right — it had to retain all the benefits people expected from Da-Lite and be able to operate wirelessly without fail.

Among the engineering challenges was how to get Da-Lite’s signature HD screen surfaces onto a smaller roller. “We had to scale down the surface technologies to work in a smaller housing,” Schwartz says. “It did take some engineering to get there, to ensure the surface would stay smooth. We also had to do thorough cycle testing with the weight of our screen, understanding how long between charges and what the life expectancy would be. We had to be very sure of those answers and also be able to support a five-year warranty.

“That testing is something we do all the time and take for granted. But in this case, the testing itself was an engineering project — ‘how do we get this to run on a timer 24 hours a day when nobody’s here, when it’s all wireless communication and a battery that needs to be charged?’ Our testing engineers figured out how to rig a remote and add a counter to do the cycling and monitor it. As a result, we can confidently say we can run 200 up and down cycles on a single charge.

“So our design and operations engineers really worked together to adapt this to the smaller roller size, come up with something lighter, something that’s easy for a couple of people to hang on the wall, but strong enough to cycle over and over,” Schwartz says.

“One of the things we were looking at also was the end user and whether they would follow through with the charging,” Cox explains. “Brian was able to work with the team to get a PoE adapter, that would simplify that maintenance significantly.” The screen can permanently plug into the network (if available) and self-charge. The screen also comes with a 10-foot USB cable for manual charging (about every three months) where a network connection is not available right at the unit. An available app monitors battery life (available with the WiFi bridge) and there is also an indicator light on the housing.

“We saw potential for cost savings where people would not have to involve an electrician, where installation was in and out, and the end user could upgrade from a fixed screen to an elegant, motorized solution that was affordable,” Cox says.

For integrators who are working on architecturally sensitive projects such as museums or historical building renovation, or in any situation where aesthetics are important, it provides an option to go with a retractable screen pretty much anywhere the lighting will support. Schwartz says the units are preconfigured to be compatible with Control4 and can integrate through the WiFi bridge with third-party control systems, such as Crestron, opening up integration opportunity on the software side.

Screen Surfaces – Tensioned Designer Contour

Progressive 0.9 is a front projection screen surface designed for high resolution up to 16K. Recommended for laser projectors with ultra-short, short and standard throw lenses, its subtle gray appearance enhances image color and contrast and is available in sizes up to 16’ high seamless. This premium surface is ideal for projects with edge blending and small and large venue projection needs and is GREENGUARD and GREENGUARD Gold certified to meet and exceed stringent standards for indoor air quality.

Progressive 1.1 is a front projection screen surface designed for high resolution up to 16K. Recommended for laser projectors with ultra-short, short and standard throw lenses, its neutral white appearance provides brilliant image color and is available in sizes up to 16’ high seamless. This premium surface is ideal for projects with edge blending and small and large venue projection needs and is GREENGUARD and GREENGUARD Gold certified to meet and exceed stringent standards for indoor air quality.

Real-Life Results

The idea was simple — to bring a retractable screen option into more installations. “We knew there was a need,” Schwartz says, “because with new products, we always reach out and gather empathy — that’s really a core part of Legrand as a whole. A lot of input and detail went into this product.”

That work was almost immediately applicable to a real-life installation. The Blake School in the Twin Cities is a private prekindergarten-through-grade 12 school with multiple campuses and unique, historical rooms from the early 1900s, says Shane King of Minneapolis-based EPA Audio Visual.

“They’ve come to us before with their very unique rooms, but this is the first time we had this option to offer. In this particular situation, we were dealing with older woodwork in between a series of high windows. It was the desired wall for the screen but there was no cabling and we were not going to be able to add it,” he says.

Previously, the school had been using a manual screen and had wanted to upgrade that screen for some time. “It wasn’t re-ally practical to upgrade, because they didn’t want to replace it with just another manual screen and the wired motorized units that were available were too expensive and not practical for the space,” King says.

The new wireless option fit the bill. “It accomplished the goal with very minimal integration, labor, and costs. It worked as advertised and did exactly what it needed to do,” King adds.

“We’ve installed Da-Lite screens in the past,” King continues. “We’ve put in plenty of their HD Progressive screens, and from experience we know they meet user expectations, especially in environments using laser projectors. We anticipated that the screen material would deliver the same high resolution as we were accustomed to.

“The benefit of this screen is two-fold,” King explains. “In any project, some individuals are concerned about the aesthetics, while other users — including teachers and instructors — care more about the quality of the image, because they’re using it every day and that’s the most important aspect. So this option re-ally hits both sides: mechanically, it works great in a challenging environment in terms of being able to put it into a place where we can’t get cabling or electrical, and it still accomplishes what it is supposed to in terms of being a high-quality projected image.

“We talked through everything prior, with the manufacturer as well as the end user, including what the options were for charging,” King says. “You can charge the included power supply by PoE with a network cable to the screen and set it up like a trickle charge, or for options like this, it was an extension cord to AC using the provided adapter. An overnight charge gives them about three months.

“We’d been discussing an upgrade for this project for several years,” King says, “but within their budget there was not really a good solution. There was not a suitable replacement for their screen that made the upgrade worth it. Once this product was introduced, it was a perfect fit.

“I think this opens up a lot of opportunities to revisit challenging rooms or installs where there wasn’t really an ideal solution for them,” King continues. “Also, a lot of people have the attitude ‘if it ain’t broke don’t fix it,’ so there were not a lot of opportunities to replace a manual screen with another manual screen. Now there is.

“The other benefit is being able to keep the install low-voltage, so it stays in our scope,” King adds. “That saves not only budget, but also the need to identify and hire an electrician and split scope. It may be an incremental money-saver, but from a budget and management standpoint, it opens up the opportunity to the end user to consider doing more rooms or allocating that extra money towards a more premium projector or audio system.

“It simplifies the interaction on the trades and the scheduling that goes with that,” King continues. “Our speed to install can be a little quicker, because we’re not dependent on coordination with other trades.

“In this case the only challenge we ran into was environmental — the way the installation occurred in between windows and window treatments. We had to field engineer how to clear the windows, which we were able to do relatively easily. This kind of flexibility is key. It opens a lot of different opportunities, for example, to use a different wall within a particular room that might not have been practical previously due to power limitations or aesthetic concerns. When you are dealing with older buildings, brick and block, when a surface raceway can be unsightly and add more costs, you have an option that doesn’t involve drilling into sensitive artwork or trying to dress up cabling pathways.

“In the past there were really two options, a simple manual screen or a premium electrical screen that requires higher volt-age in those environments where that’s feasible, and there’s an expectation and budget along those lines,” King concludes. “Or they might even be relying on a cart since so many rooms require video now. But, of course, that greatly limits the screen size. Now, we have a better option, so customers that are accustomed to or already own a two-piece projector setup can maintain a large, room-appropriate image size — larger than any flat panel — and something unique and cool that’s within their budget. It’s a middle ground we can offer now that also opens up other conversations and opportunities.”

All News

All News